In patient rooms, around the country, medical teams face a persistent problem: how to treat patients with a highly contagious disease without spreading the illness themselves. Though we are several months in to the COVID-19 pandemic, health care providers still lack a sufficient supply of personal protective equipment (PPE).

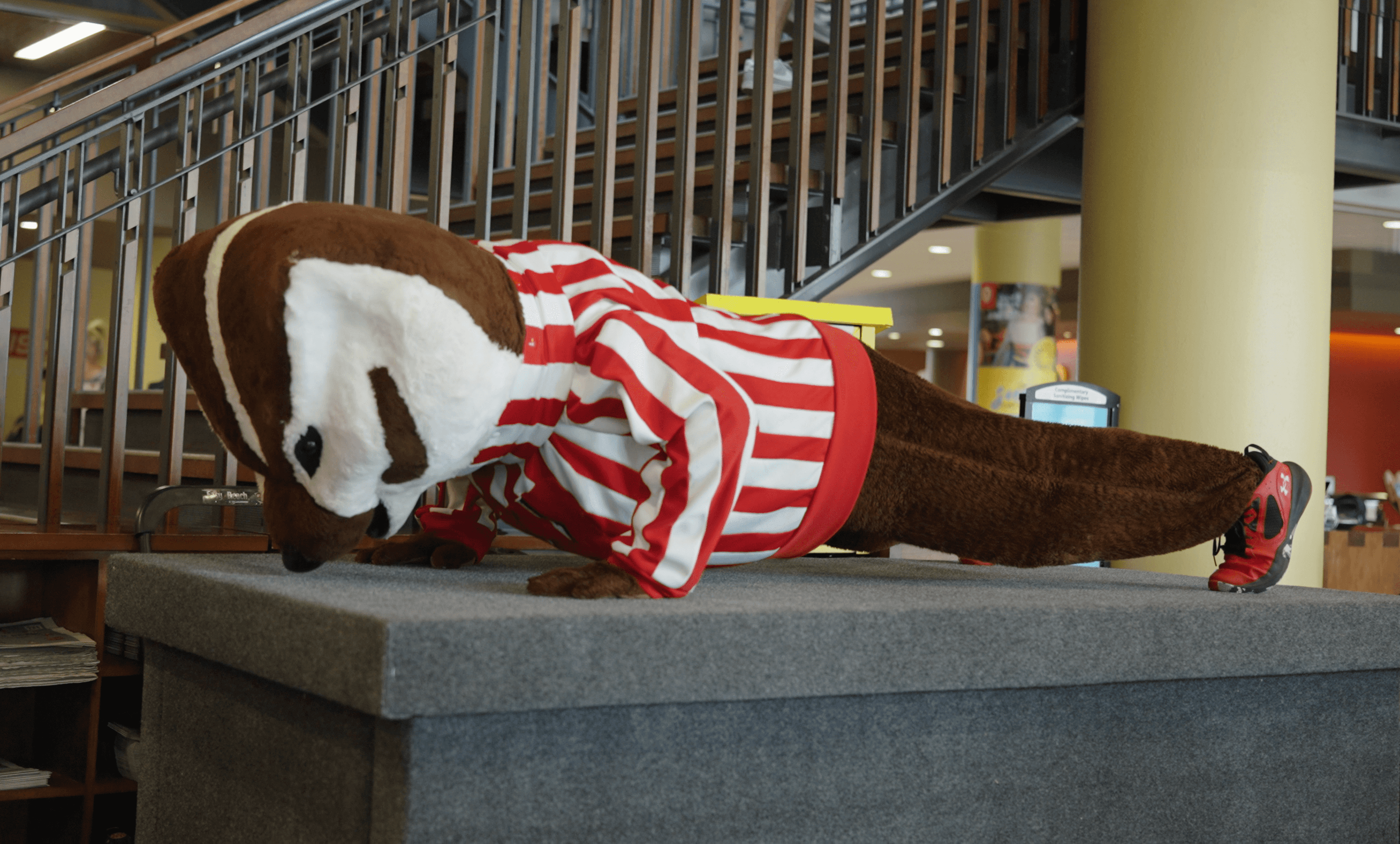

Enter the BADGER: the Box of Aerosol and Droplet Guarding and Extraction in Respiratory infections. Designed by UW–Madison surgery professor Hau Le and a team of UW doctors, engineers, and Sector67, the BADGER is a person-sized negative pressure isolation chamber. Think of it as PPE that surrounds a patient rather than a doctor or nurse: while regular PPE keeps a virus-free zone around each health care worker, the BADGER keeps an infected zone contained around a patient. This allows health care professionals to give treatment without risk of exposure to coronavirus.

“The device has a reusable clear shell and other disposable accessories,” says Le. “The accessories are commonly available in any hospital, such as surgical gloves, tubing, filters, drapes, tapes. Put together, they create a semi-sealed device that does the job. We designed it so that it could be made easily and cheap.”

Though Le’s primary appointment is in the Division of Pediatric Surgery, he’s also affiliated with the UW’s Department of Biomedical Engineering. He says his design took inspiration from an intubation shield created by Taiwanese physician Hsien-Yung Lai to protect anesthesiologists as they were placing breathing tubes in patients. Le then improved the design by turning the shield into a semi-sealed chamber.

“Even though the WHO said that COVID-19 [doesn’t] spread via airborne [transmission], there has been emerging evidence that it does,” Le says. “Therefore, I wanted to create a box that would not only be able to shield large droplets but also the airborne particles that that we don’t see.”

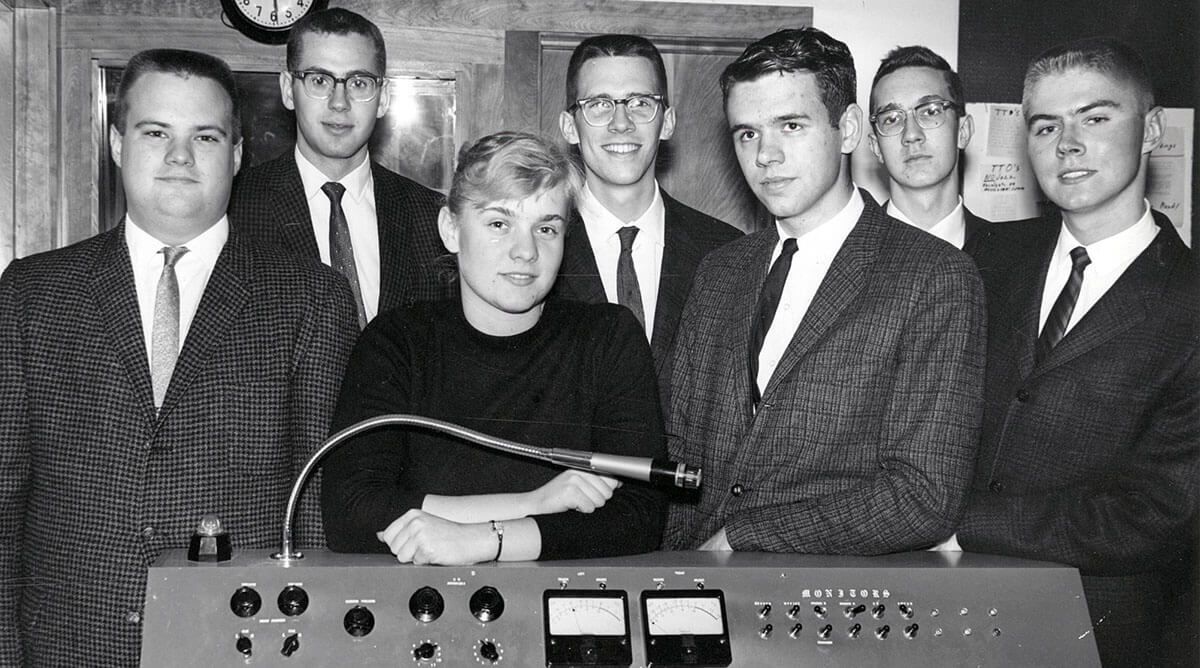

Le consulted with Peter Adamczyk and UW–Madison Engineering Support for Covid-19 to turn the design into a prototype. Now BADGERs are being fabricated by Madison’s Sector67, a collaborative design and production facility. The BADGER is made available as an open-source design at the UW-Madison MakerSpace, directed by Lennon Rodgers, for anyone to use while Le’s team and his collaborators continue to test and improve its effectiveness. The UW Hospital is currently testing them in a clinical setting. Le hopes that the BADGER will prove helpful, not only for COVID-19 patients in Wisconsin, but also to inspire further improvements.

“The purpose,” he says, “is to spread the word so that other places can build their own devices based on the work that we’ve done.”